Overview

AC Hargreaves purpose built transformer workshop was established in response to the industries need for specialised transformer services, AC Hargreaves modern workshop offers refurbishments, rewinds, tank modifications and specialist testing including site oil treatment and testing. Our facility is equipped with a 32 tonne high lift overhead crane, gas fired vacuum dry out oven and a fully equipped testing facility, ensuring quality and reliability of work undertaken is cost effective and guaranteed. We boast a team of industry specialists with exclusive transformer backgrounds, committed to the electricity industry and devoted to provide the highest level of quality work. Quality accredited to ISO 9001 we are committed to ensure fast project turnaround to meet your outage requirements. Capability to Service and Refurbish transformers across the product range including:

- Distribution transformers

- Transmission transformers

- Padmount and Kiosk transformers

- Generator transformers

- Auto transformers

- Transportable substation type

- Rectifier and furnace transformers

- Oil filled reactors

- Dry type transformers

- Air cooled reactors

Capabilities

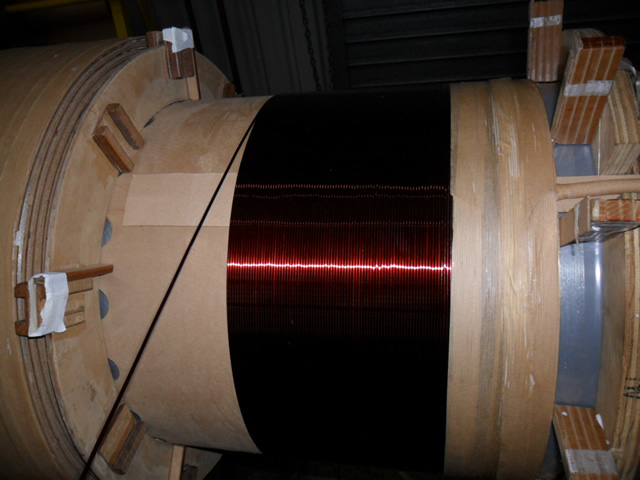

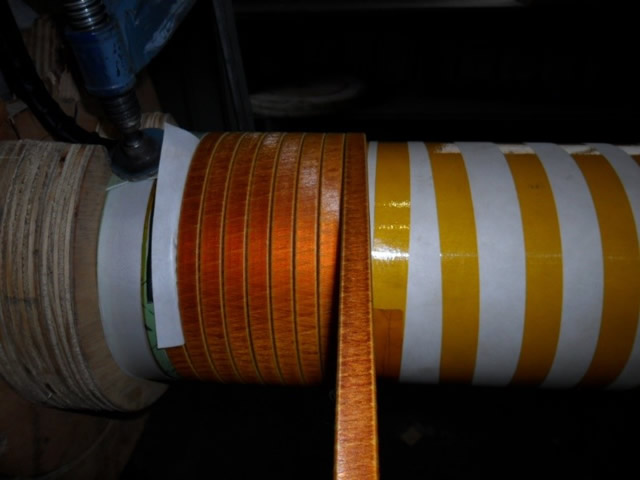

Rewinds

Our specialist rewind facility can fully rewind or partially rewind all types of transformers both oil and Dry Type, we are equipped with 3 purpose built winding machines together with large stocks of transformer insulation material and standard components. Our team can re-engineer and rewind critical plant in very short times - thus saving plant downtime and costly outages.

- Recondition, repair and rewinding of oil filled, dry-type core-form, and shell form transformers

- 10 KVA - 25,000 kVA, <= 69 KV - rectangular layer, circular layer, circular disc, circular helical and shell form design

Refurbishments

Our workshop is fully equipped to provide fast turn around, quality midlife transformer refurbishment, repairs and proof testing. Staffed by industry specialists who provide qualitative and innovative solutions in respect to transformer repairs and refurbishments requirements.

Our 2,000m² workshop accommodates oil filled and Dry Type transformers up to 25 MVA or 32 tonne active part and is equipped with two purpose built drying ovens capable of drying transformers up to 66kV. Proof and diagnostic testing is conducted in house via our fully equipped test bay capable of 300kV testing.

Transformer midlife refurbishment specification:

- Incoming electrical tests

- Assessment and report

- De-tank core and coils

- Wash down core and coils with clean dry oil

- Oven process and monitor IR progress of core and coils

- Secure and tighten all bracings, connect and brace all leads

- Clean and prepare transformer tank and parts and paint using 2 Pack Paint Systems

- Re-tank core and coils

- Renew all gaskets using proven resilient systems

- Refurbish tap selector

- Supply of new oil or treat oil through degassing and vacuum plant

- Carry out final test on transformer

- No load ratio test

- Winding resistance

- Separate source hi-pot

- Full voltage test

- Insulation resistance and polarization index

- Oil breakdown test

- Provide full written report with all test results and photos

Dry-outs

Moisture in oil comes from various sources, manufacturers residual, leaking gaskets, inefficient breathers, oil oxidization and cellulose equilibrium (between insulation system and oil). Moisture in transformers causes the following:

- Increased aging of the transformer

- Decreased electrical strength

- Gassing into oil at high temperatures

Our purpose gas fired ovens coupled with our vacuum capability ensures all transformers are dried and processed to the highest insulation integrity, proof testing via DLA and oil testing is conducted to certify final ready for service state.

Thermal Upgrades

Transformer upgrading can be a cost effective way to deliver higher performance of assets, thermal increases can be obtained through addition of fans, oil pumps and or rewinding active components. AC Hargreaves has the capability to analyse thermal rating criteria which includes taking into account conductor size, current density, ratings of tap selector contacts and leads, bushing stems and coil configuration.

Field Refurbishment

Our comprehensive transformer field services include repairs, inspections, electrical testing, oil filtration & testing. Our specialist transformer staff provide safe reliable field services including:

- Re-gasketing

- Coolers, valves, fans, controls, wiring and accessories supply & replacement

- Pump rebuild and replacement

- Painting

- Bushing Replacement

- Transformer relocation

- Assembly, installation and pre-commissioning

- Internal Inspection and repair

- No-load tap changer repair

- Oil filtration and degasification

- Vacuum filling

- Vacuum dry-out

- Oil sampling services

- Load Tap Changer Inspection and Maintenance

- Electrical testing

Oil Processing

AC Hargreaves workshops and field services utilise high vacuum oil treatment plants, and our mobile trailers are equipped with inline moisture monitoring equipment to ensure transformers are circulated and refilled to exceed relevant standards.

Portable online extended duration vacuum units are available to hire and are specially designed to remove moisture over a period of time. Long duration drying utilises the transformers thermal cycles to pass oil from the insulation system to oil and removed via vacuum oil separation.

Diagnostic Testing

Diagnostic testing is crucial when plant has failed or has key fault gas indicators of pending failure, the transformer division utilises High Voltage DLA testing, SFRA, Doble Reactance testing, PD testing coupled with experienced technician to test, analyse, predict and provide solutions on transformers both in the field or workshop.

Oil sampling, testing and analysis is a key tool utilised in the early prediction of transformer faults our trained team utilise test reports and transformer trending data to assist end users in determining maintenance or repair strategies.

Onsite Inspection & Advice

Our transformer specialists are available via phone or to visit sites across Australasia providing mining, mills, refineries, utilities, manufactures and electrical service centres advice on transformer and major plant life cycle solutions and or diagnostic investigations.

Site solutions are specific however may involve:

- Transformer operational advice

- Oil sample analysis

- Installation and operating condition reports

- Transformer repair options

- Cooling upgrades

- Replacement radiator and sizing

- Oil handling and leak prevention

- Dry Type cleaning and maintenance

- Up-grade and relocation of equipment

- Silica gel supply and replace

- On load and off load tap changer servicing

- Oil change-over, oil circulation and particle reduction

- Oil leak transformer repair on site along with any transformer gasket changes

- Compound filled HT box change out

New Transformers & Parts

AC Hargreaves access cost effective transformer pricing from 10kVA to 400MVA and are able to provide independent advice on the best product for your application. Through business partnering

we are able to offer transformer and switchgear at competitive pricing, including oil filled Padmounts, Ground Mounts, Power transformers, Rectifier transformers, Dry Type and special purpose transformers.

Product listing:

- Oil filled transformers

- Dry Type transformers

- Power transformers

- Oil sales

- Breathers

- Replacement radiators

- Machined tap changer parts

- Gaskets

- Bushings

- Temperature instruments

- Pressure relief devices

- Touch-up paints

- Gauges

Image Gallery